Maintaining Aerial Equipment’s Hybrid Systems

by Zach Gilmor - Product Manager On May 21, 2020, 03:00 AM

Subscribe To Aerial Pros

Filter by tags

The idea and purpose of hybrid machines have not really changed since their introduction, but the execution of these machines has evolved significantly along with the technology that powers them. Many of today’s hybrid MEWPs can offer the flexibility to be dropped onto an unimproved jobsite before a structure is built and then move indoors for finish work. This flexibility is what makes owning and operating these machines so attractive for rental stores and contractors. And, many rental owners of hybrid equipment are also realizing the total cost of ownership (TCO) benefits that come from a well-designed hybrid system.

But, saying the words “hybrid” can create anxiety in service technicians who are more familiar with diesel-powered machines. Right now, there still seems to be a certain amount of fear of the unknown associated with the maintenance of hybrid systems.

Admittedly, at the surface, the overall design concept of today’s hybrid aerial equipment, which is aimed at powerful performance with a smaller engine may seem counter intuitive. However, digging a little deeper into the individual machine components, service technicians will notice many similarities to diesel- and electric-powered counterparts, finding them to be simple machines to maintain. Service technicians will also notice some components that even reduce the need for maintenance.

Hybrid System Maintenance

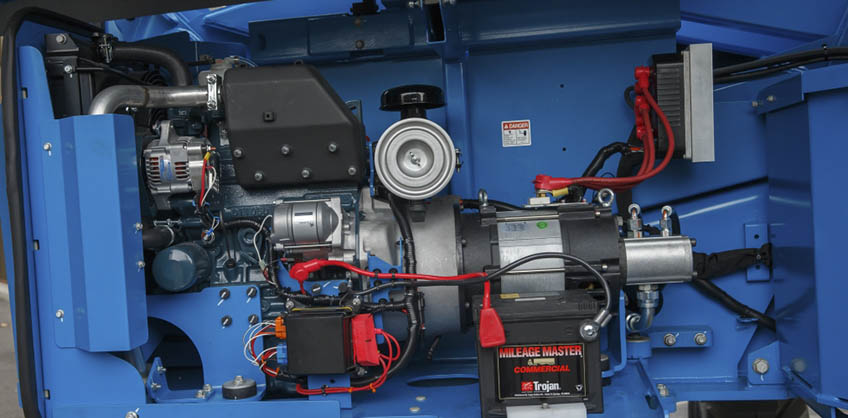

Surprisingly, hybrid equipment is often simpler, and easier to do maintenance on. Even though hybrids may sound like they would be more complex to maintain, they are actually developed by packaging together simple, existing technologies in a new way — today’s hybrid equipment design and technology is fundamentally based on electric machines. For example, on Genie® FE (FE stands for fuel-electric) hybrid MEWPs, the drive systems and controls come from our electric rough terrain scissors, and the simple, mechanically controlled engines are taken from our smaller boom lifts.

machines. For example, on Genie® FE (FE stands for fuel-electric) hybrid MEWPs, the drive systems and controls come from our electric rough terrain scissors, and the simple, mechanically controlled engines are taken from our smaller boom lifts.

Because of the commonality of components, the similarities between hybrid and diesel-powered lifts include basic engine and hydraulic system maintenance, such as regular checks and changing of engine oil, filters, hoses and so on, per the manufacturer’s recommended guidelines.

And similarities with electric-powered lifts include routine battery maintenance, electrical component inspections and so on, according to the manufacturer’s recommended guidelines.

Because much of the equipment in today’s aerial and rental fleets are electric machines, service technicians are often more familiar with the internal make-up and components of electric machines compared diesel machines, which makes maintenance tasks on hybrid equipment less daunting.

It is important to note that a very small number of new components — for example, the hybrid system clutch — are specific to hybrid units; however, none of these components requires any special maintenance, as long as owners and operators are following the manufacturer’s recommended guidelines for safe use and preventive care of these MEWPs.

Charging System Maintenance

Aside from regular inspection and routine checks of a MEWP’s electrical connections and wiring, per the manufacturer’s specifications, often no other maintenance is required on a hybrid machine’s charging system.

Even AGM (Absorbent Glass Mat) batteries, which are standard on all Genie FE hybrid models, are sealed and maintenance-free. Genie chose AGM batteries for its hybrid solution, in part, because these do not require the added maintenance for checking/topping off the flooded lead acid batteries found on other hybrid and electric models, which further reduces shop time. And, these batteries are not propriety to Genie with hard-to-source parts when maintenance is required, saving money.

Drive System Maintenance

Like maintenance checks on the hybrid system, regular maintenance of hybrid MEWPs’ drive systems is very similar to diesel-powered machines. For instance, hub maintenance is essentially equivalent between the two types of machines, and inspections of electrical wiring and connections typically replace those of hydraulic motors and lines on diesel machines. The full-electric drivetrain features maintenance free AC drive motors, with higher efficiency than standard hydraulic motors and without hydraulic oil leakage and maintenance.

Special Maintenance Considerations

It important to note that not all hybrids are created equal. That said, as Genie was designing its FE hybrid technology, ease of service was one of the most significant requirements from customers. Responding to that need, the Genie FE hybrid system was designed around existing technology, packaged in a new way, so service technicians already have the skills and equipment necessary to service these hybrid MEWPs.

In addition, today’s MEWPs are now intelligent enough to assist technicians with troubleshooting with features such as a platform display to display fault codes, ease sensor calibrations and set software options, which contributes to this hybrid system’s reputation in the field of being easy to service and maintain.

Maintenance is a Commitment

The good operating condition and extended life expectancy of any MEWP — diesel-, electric- or hybrid-powered — is largely influenced by regular care and maintenance. Preventive maintenance is a commitment.

With more and more hybrid MEWPs showing up on jobsites, admittedly, at the surface, today’s hybrid technology can offer a revolutionary new approach in machine concept and design, increasing application versatility without sacrificing power or productivity, to traditional power options. But digging down into the design details of these modern hybrid systems, services technicians will find that these systems are built with many of the same components as existing diesel and electric powered machines, plus include components that actually help to minimize maintenance and reduce time in the shop — all good reasons to shake the hybrid anxiety and keep these versatile machines in rental fleets.

Related Posts

How It Works: The Genie® FE Hybrid Technology

Power systems for mobile elevating work platforms (MEWPs) continue to evolve, just like the machines they drive.

Continue Reading

Robust Hybrid Technology: A “Must Have” in Today’s Rental Fleets

Responding to worldwide demand for high-performance yet environment friendly aerial access equipment, and to increasingly stringent emissions and noise regulations, particularly in European markets, hybrid technology today, especially in rental equipment fleets, must be able to perform a wide range of indoor and outdoor applications, increasing utilization rate for rental businesses and decreasing cost of operation for end users.

Continue Reading

Using MEWPs in Different Markets and Applications

Mobile elevating work platforms (MEWPs) are used in a variety of work environments.

Continue Reading